Automated Inspection at soft drink bottling plant

Project of ‘Image Processing’ course ( Master’s First Semester at University of Burgundy, January 2019)

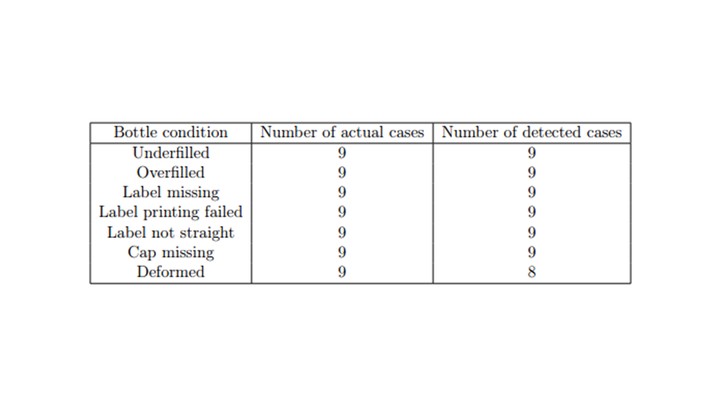

The main goal of this project was to develop a visual inspection system. The following seven fault conditions were aimed to be detected- Bottle under filled, Bottle over filled, Bottle has label missing, Bottle has label but label printing was failed, Bottle label is not straight, Bottle cap is missing, and Bottle is deformed in some way. Background studies include extracting region of interest, computing mean gray level, binarizing any chosen region of interest with a particular thresholding, computing percentage of black pixels and comparing to normal bottle values, extracting red channel, edge detection and obtaining connected components & their bounding boxes, finding largest bounding box, comparing area, height & width to the normal. Depending on the fault condition different types of step were applied. And a simple graphical user interface was designed.